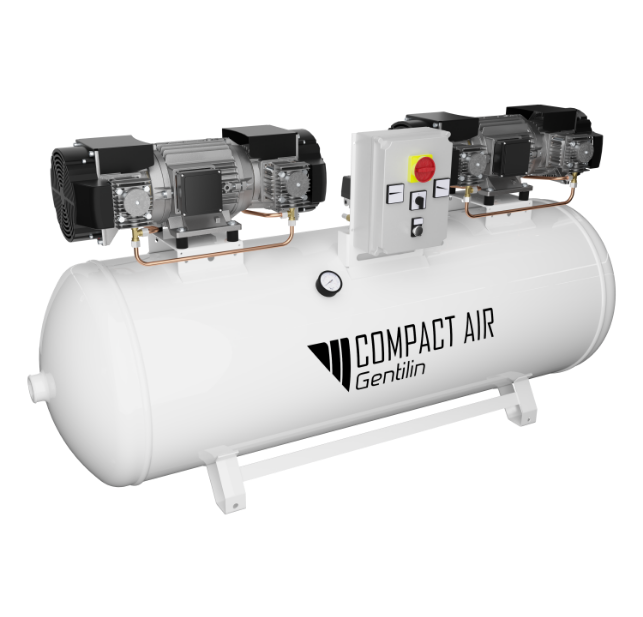

HUSH range

The concept

GENTILIN’s

HUSH range has been designed and developed to

meet the needs of highly professional applications, where

lubricated screw compressors (with the problem of oil

contamination) or SCROLL compressors (characterized by very

high purchase and maintenance costs) are usually used.

The

cornerstones of the HUSH range are the following:

- Oil free Class 0 clean air

- 24/7 continuous operation

- Life cycle of 10.000 hours

- Up to 3.000 hours maintenance-free

- Low noise emissions

These results have been achieved thanks to the combined use of different technologies:

- Patented AXXER oil free mechanical technology

- Machining and materials of aero space derivation

- Electric motors in S1

- Suction/compression labyrinth for noise abatement in both phases

- Hermetic closing of the piston chamber to reduce noise from moving parts

What can these condensed technologies guarantee within the HUSH range products?

Who are HUSH piston compressors

developed for?

Food laboratories

Biogas production (Nitrogen, etc.)

Wineries

Brewing

Milking rooms

Industrial painting

Transport (TTrain/Bus/Metropolitane)

Artificial snowmaking systems

Photovoltaic systems

Printing

Packaging

CAD/CAM

Wherever a SCROLL compressor is usually used

The range

| Power | 2,2 and 8,0 kW |

|---|---|

| Tanks | From 150 to 500 Lt |

| Air quality | Oil-free Class 0 (ISO13285) |

| Service class | 100% ON - Continuous duty |

| Max pressure | 10 bar (14 bar on request ) |

| FAD | From 330 to 1320 lt/min |

| Maintenance overhaul | 3.000 hr (K version) 10.000 hr (W version) |

| Tank treatments | Epoxy anti-rust treatment (internal/external) |

| Noise level | Quiet (68-78 dB) |

* Refferred to a continous duty at 8 bar pressure

Features

Axxer patented long-life mechanics

- Oil-free class 0

- 24/7 - 100% non-stop duty

- Up to 10.000 before first maintenance

- 10 bar operating pressure (14 bar on request)

Continuous duty 24/7

- S1 class motor

- 1400 rpm

- Low operating temperatures

Easy maintenance

- Piston rings and gaskets replacement (H 00:30/60)

- Entire pumping unit replacement (H 00:15/30)

Noise abatement

- Suction/compression labyrinth for noise abatement in both phases

- Hermetic closing of the piston chamber to reduce noise from moving parts

Optimal efficiency and durability

- High flow forced ventilation system

- Optimum cooling of the pump unit

- Increased compressor efficiency and life

Easy handling and operation

- Eeasy handling with tres pallets and forklifts

- Integrated hour meters

- Automatic condensate drain from the tank (optional)

Advantages for the end users

offer the user several advantages:

Ensuring a

healthy

workplace

Avoid production stops and consequent delays in deliveries

Avoid contamination and deterioration of treated products

Keep noise emissions within a safety and sustainable range

Minimize

rework and

waste

Optimize the

operating

costs of your equipment

HUSH Piston Compressors Technical Chart

| ESK480/270 | ESK660/270 | ESK960/500 | ESK1320/500 | CSK330/150VE 230V | CSK330/150VE 400V | ESK660/200VE | |

|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Intake Air | 48 lt/min | 660 lt/min | 960 lt/min | 1320 lt/min | 330 lt/min | 330 lt/min | 660 lt/min |

| Air delivered at 5 bar | 310 lt/min | 400 lt/min | 620 lt/min | 800 lt/min | 200 lt/min | 200 lt/min | 400 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 74 dB | 76 dB | 77 dB | 78 dB | 68 dB | 68 dB | 76 dB |

| Tank | 270 lt | 270 lt | 500 lt | 500 lt | 150 lt | 150 lt | 200 lt |

| Dimensions | 164x58x90 (124kg) |

158,2x50x93 (124kg) |

204x67x98 (340kg) |

204x67x98 (340kg) |

61x61x142,8 (71kg) |

61x61x142,8 (71kg) |

67x56,5x172,5 (114kg) |

| Working cycle | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% |

| Maintenance interval | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr |

* mandatory fields

Do you need more information on Gentilin process air compressors?

We are at your disposal, contact us here