SCROLL range

The concept

The introduction of SCROLL technology represented a definitive innovation in the landscape of oil-free applications.

GENTILIN scroll range compressors are built with highly durable materials and are certified to guarantee the user the following operational advantages:

- Oil-free CLASS 0 clean air

- Non-stop operation H24

- Mechanical maintenance at 8.000 hours

- Reduced energy cost

- Quiet operation

These results have been achieved thanks to the combined use of

different technologies:

- "HITACHI" air-endswith innovative SCROLL technology

- Class 1 "A&G" electric motors

- «SIEMENS» electronic components

- Premium soundproofing materials for maximum noise abatement

- Solid construction designed to simplify maintenance operations

Thanks to the use of these technologies, we have been able to guarantee our customers:

up to 10,000 hours

without maintenance

Who are SCROLL piston compressors

developed for?

Medicalcenters and

hospitals

Dental practices

Laboratory(cad/cam)

Food

processing

Biogas production (Nytrogenecc.)

Wine making

Beer making

Milking rooms

Industrial painting

Industrial printing

Packaging

The Range

| Power | From 2,2 to 7,5 kW |

|---|---|

| Tank treatments | Epoxycoating (external) / Teflon coating (internal) |

| Air purity standard | Oil-free Class 0 (ISO 13285) |

| Duty cycle | 100% ON - Non-stop operation |

| Max pressure | Up to 10 bar |

| FAD | From 240 to 850 lt/min |

| Maintenance overhaul* | 8.000 hr |

| Noise level | Ultra-quiet (64-67 dB) |

*Referred to a 8 bar non-stop operation

Features

Noise abatment

- A labyrinth system creates a barrier against noise propagation, reducing the air intake noise to a minimum

- High-density sound-absorbing panels are applied to all the internal surfaces, reducing both high and low frequencies ensuring an acoustic abatement without equal

Efficiency and optima durability

- High-flow forced ventilation cools the compressor module keeping the working temperature well below critical point. This system guarantees a higher compressor efficiency and an extended life cycle

Easy maintenance

- Change of seals and bands H 01:00

- Replacement of whole pump H 00:30

24/7 Non-stop operation

- Heavy duty «HITACHI» scroll air-ends

- S1 class motors

- Low working temperatures

Long-life mechanics

- Continuous duty 24/7 non-stop

- 8.000 hours without maintenance

- Up to 3.090 lt/min air flow

- Up to 10 bar operation

Low air temperature

- The smooth working rotative SCROLL system ensure a low temperature air flow out of the compressor, that in turns simplify the management of post-compression applications

Advantages For The End Users

offer the user several advantages:

Ensuring a

healthy

workplace

Avoid production stops and consequent delays in deliveries

Avoid contamination and deterioration of treated products

Keep noise emissions within a safety and sustainable range

Minimize

rework and

waste

Optimize the operating costs of your equipment

SCROLL - The range

Basic

- 2,2 Kw

- Direct start-up

- With or without tanks (270/500 L)

- With or without dryers

Premium

- From 2,2 to 30 kW

- Star/delta start-up

- PLC control

- With or without tanks (270/500 L)

- With or without dryers

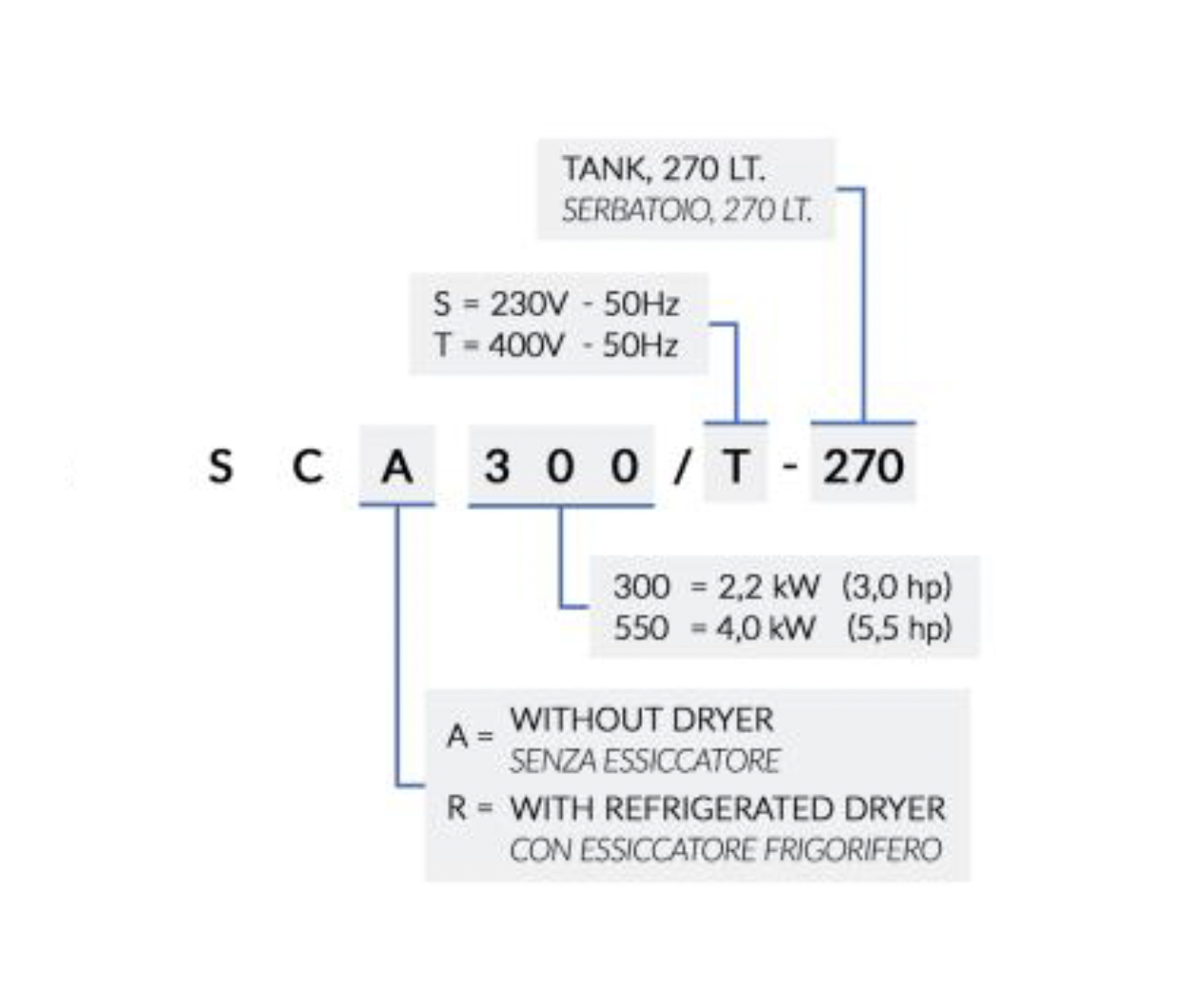

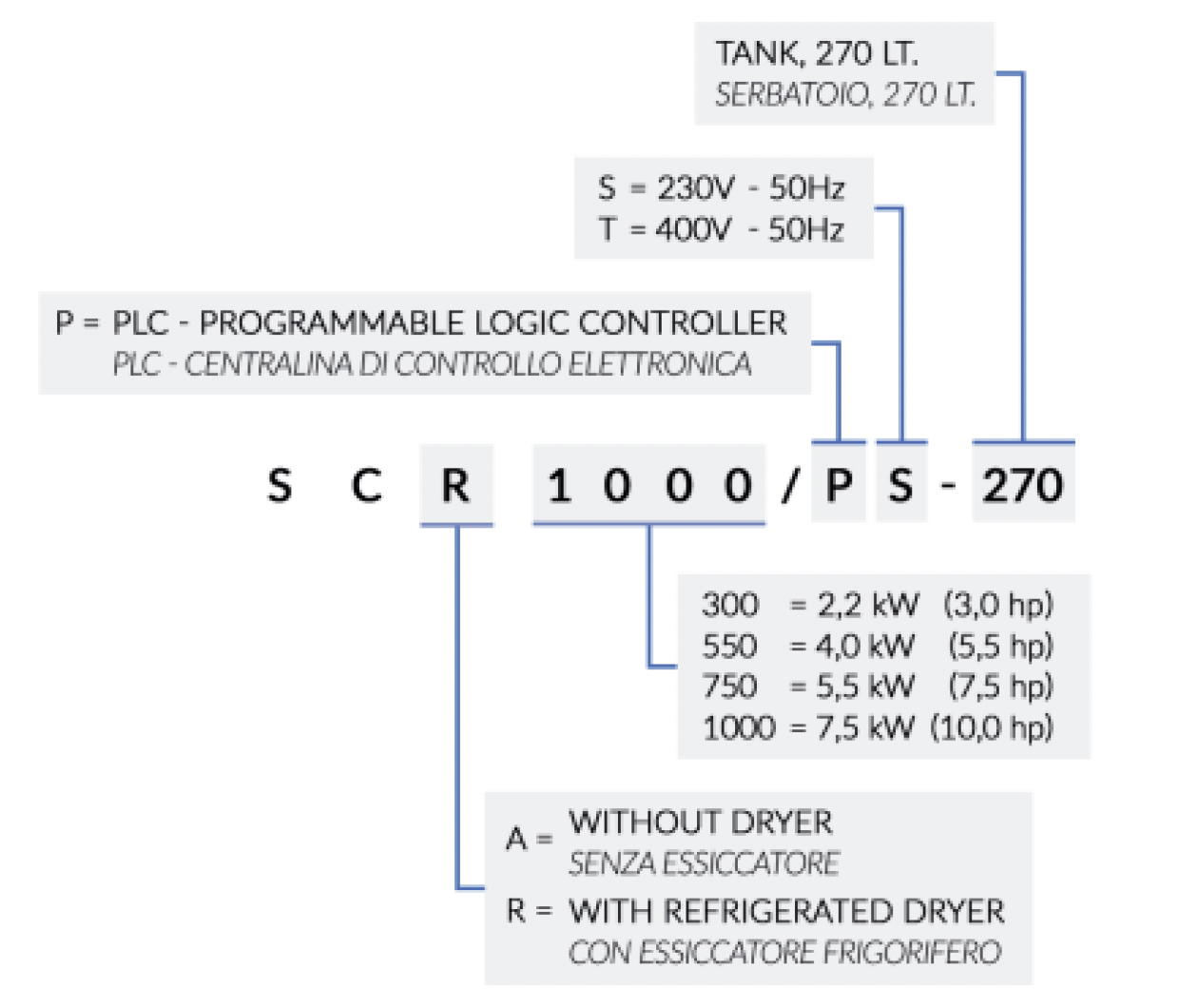

SCROLL - Model configuration

Basic Models

Premium Models

SCROLL BASIC Piston Compressors Technical Chart

| SCA300/S | SCA300/T | SCR300/S | SCR300/T | SCA300/S-270 | SCA300/T-270 | SCR300/S-270 | SCR300/T-270 | |

|---|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Intake Air | - | - | - | - | - | - | - | - |

| Air delivered at 5 bar | 240 lt/min | 240 lt/min | 240 lt/min | 240 lt/min | 240 lt/min | 240 lt/min | 240 lt/min | 240 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 64 dB | 64 dB | 64 dB | 64 dB | 64 dB | 64 dB | 64 dB | 64 dB |

| Tank | - | - | - | - | 270 lt | 270 lt | 270 lt | 270 lt |

| Dimensions | 65x57x86 (128kg) | 65x57x86 (128kg) | 84x57x86 (158kg) | 84x57x86 (158kg) | 119x61x148 (198kg) | 119x61x148 (198kg) | 119x61x148 (228kg) | 119x61x148 (228kg) |

| Working cycle | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% |

| Maintenance interval | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr |

SCROLL PREMIUM Piston Compressors Technical Chart

| SCA300/SP | SCA300/TP | SCA550/TP | SCA750/TP | SCA1000/TP | SCR300/SP | SCR300/TP | SCR550/TP | SCR750/TP | SCR1000/TP | |

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Intake Air | - | - | - | - | - | - | - | - | - | - |

| Air delivered at 5 bar | 240 lt/min | 240 lt/min | 410 lt/min | 630 lt/min | 850 lt/min | 240 lt/min | 240 lt/min | 410 lt/min | 630 lt/min | 850 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 64 dB | 64 dB | 67 dB | 67 dB | 67 dB | 64 dB | 64 dB | 67 dB | 67 dB | 67 dB |

| Tank | - | - | - | - | - | - | - | - | - | - |

| Dimensions | 65x57x86 (128kg) | 65x57x86 (128kg) | 75x60x96 (140kg) | 75x60x96 (145kg) | 75x60x96 (148kg) | 84x57x86 (158kg) | 84x57x86 (158kg) | 101x60x96 (195kg) | 101x60x96 (195kg) | 101x60x96 (198kg) |

| Working cycle | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% |

| Maintenance interval | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr |

| SCA300/SP-270 | SCA300/TP-270 | SCA550/TP-270 | SCA750/TP-270 | SCA1000/TP-270 | SCR300/SP-270 | SCR300/TP-270 | SCR550/TP-270 | SCR750/TP-270 | SCR1000/TP-270 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Intake Air | - | - | - | - | - | - | - | - | - | - |

| Air delivered at 5 bar | 240 lt/min | 240 lt/min | 410 lt/min | 630 lt/min | 850 lt/min | 240 lt/min | 240 lt/min | 410 lt/min | 630 lt/min | 850 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 64 dB | 64 dB | 67 dB | 67 dB | 67 dB | 64 dB | 64 dB | 67 dB | 67 dB | 67 dB |

| Tank | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt | 270 lt |

| Dimensions | 119x61x148 (198kg) | 119x61x148 (198kg) | 119x61x158 (215kg) | 119x61x158 (220kg) | 119x61x158 (223kg) | 118x61x147 (228kg) | 118x61x147 (228kg) | 118x61x157 (265kg) | 118x61x157 (270kg) | 118x61x157 (273kg) |

| Working cycle | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% |

| Maintenance interval | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr | 8.000 hr |

* mandatory fields

Do you need more information on Gentilin process air compressors?

We are at your disposal, contact us here